Corporate Profile

Xin Point Holdings Limited (XPHL)is listed on the main board of the Hong Kong Stock Exchange, and is the holding company of Huizhou Keen Point Precision Plastics Co., Limited.

XPHL is a global solutions provider of one-stop surface decoration. XPHL operates a complete production network, with headquarters located in Huizhou, China and production bases strategically located around the world. As of December 2025, XPHL employs more than 5,100 people worldwide.

Throughout the developing history of the industry, XPHL has progressively evolved into a leading provider of one-stop surface decorations, organically integrating various processes such as tooling, molding, electroplating, painting, PVD, laser etching, printing, lamination, Carbon Fiber and Thixomolding. Recently, Xin Point has developed new business units like ambient light products, LCD deco frames, seating components and A/B/C pillars. In 2024, Xin Point patented our CPP process (Hexavalent Chrome Free) technology and was formally nominated as a development partner by an overseas customer.

XPHL spares no effort in its response to new eco-friendly production policies. XPHL is continuously developing and applying sustainable materials and technologies, minimizing pollution, and optimizing the disposal of industrial wastewater, gas exhaust, and other residual materials.

Established in Huizhou

01571

.HK

Stock Code

Global Locations and Offices

Number of Employees

Total Production Base Area (m²)

Patents and Certifications

Customers

Awards

Valeo Supplier Partner Quality Excellence 2024

Kostal Supplier Excellence Gold Award 2024

Tianma Supplier Partner Award 2024

Valeo Supplier Quality Excellence Awards 2023

GM Supplier Quality Excellence Award 2024

GM Supplier Quality Excellence Award 2023

GM Supplier Quality Excellence Award 2022

TRCZ Best Performance Supplier 2021 Gold Awards

2018 GM China Supply Chain Green Partner

Metal appearance elastic automotive decorative parts and their preparation methods June 28, 2022

Injection molding machine based on in mold spraying September 14, 2021

A production line and process method for laser engraving on chromium September 3, 2021

Injection mold automatic water blowing system July 30, 2021

Mold ejection structure for reducing plastic injection molding adhesive powder September 15, 2020

Transfer fixture for injection molding of three-dimensional aluminum foil in mold September 15, 2020

Composite Structure and Preparation Method April 19, 2019

Color adjustable metal laser engraved automotive interior parts June 25, 2019

A coating structure for automotive decorative parts August 10, 2018

Titanium basket used in electroplating field for loading anodes May 18, 2018

Coarse liquid regeneration system applied in the field of electroplating May 18, 2018

Coarsening solution regeneration tank applied in the field of electroplating May 18, 2018

A chromic acid recycling device March 22, 2017

A plastic surface coating treatment process March 8, 2017

A car decoration structure with PVD laser engraving pattern January 4, 2017

ISO50001Huizhou Keen Point Precision Plastic Co., Ltd. EN

ISO14001Jiujiang Xin Point Automotive Components Co,. Ltd. EN

IATF16949 Jiujiang Xin Point Automotive Components Co,. Ltd.

ISO14001 Tianjin Jinxin Precision Plastic Component Co,. Ltd. EN

ISO14001 Tianjin Jinxin Precision Plastic Component Co,. Ltd. CN

IATF16949 Tianjin Jinxin Precision Plastic Component Co,. Ltd. CN

ISO14001 Huizhou Xin Point Surface Treatment Co., Ltd. EN

ISO14001 Huizhou Xin Point Surface Treatment Co., Ltd. CN

IATF16949 Huizhou Xin Point Surface Decoration Co,. Ltd. EN

IATF16949 Huizhou Xin Point Surface Treatment Co,. Ltd. CN

ISO14001 Huizhou Keen Point Precision Plastic Co., Ltd. EN

ISO14001 Huizhou Keen Point Precision Plastic Co,. Ltd. CN

IATF16949 Huizhou Keen Point Precision Plastic Co,. Ltd. EN

IATF16949 Huizhou Keen Point Precision Plastic Co,. Ltd. CN

ISO14001 Huizhou Keen Point Surface Finishing Co., Ltd. EN

ISO14001 Huizhou Keen Point Surface Treatment Co., Ltd. CN

IATF16949 Huizhou Keen Point Surface Finishing Co,. Ltd. EN

IATF16949 Huizhou Keen Point Surface Treatment Co,. Ltd. CN

ISO14001 Changzhou Xinsheng Automotive Components Co,. Ltd. CN

IATF16949 Changzhou Xinsheng Automotive Components Co,. Ltd. CN

Development History

2002

2002

Set up Haoyu Industrial, the predecessor of Huizhou Keen Point Electronics Co.,Ltd to engage in production and sales of electronic and chemical products

2004

2004

Expand Huizhou Capacity, Set up Wuxi new plant

2006

2006

Start automotive parts manufacture

2008

2008

Set up German branch Keen Point(Europe)GmbH

2013

2013

Set up US branch Xin Point North America Inc.

2014

2014

Xin Point Holdings Limited was incorporated in Cayman Island — Expanded new production bases in Huizhou and Wuxi

2017

2017

Listed on HKEX, 01571

2019

2019

Set up Huizhou Ronai Technology Co., Ltd

2021

2021

Mexico Plant SOP

2023

2023

Jiujiang Plant SOP

2025

2025

Malaysia Plant SOP (Sep. 2025)

Company Culture

Mission

Leading industry development, fostering the growth of our employees.

Vision

To be experts and leaders in the plastic surface treatment industry.

Core Values

Integrity at the forefront of all we do.

Corporate Guideline

We aim to establish a leading technological enterprise in the automotive interiors and exteriors industry, with the philosophy of "Human Oriented, Prevention Upmost". We adhere to the promise of "Safety First, Prioritize Sustainability, and Quality Driven", focusing on teamwork and data-based management. Striving for zero defects, as well as implementing continuous improvement to meet applicable regulations, customer and industry requirements through constant adaptation of competitive products and services.

Management Team

Ma Xiaoming

Executive Director and Chairman of the Board

Mr. Ma Xiaoming, born in 1966, is the Executive Director and Chairman of the Board. He is also the Chairman of the Nomination Committee and a member of the Remuneration Committee. He is primarily responsible for the Group's strategic planning and development, and oversees the Group's operations and management through regular meetings with senior management. He was appointed as a director on August 28, 2014, and was appointed as Executive Director and Chairman of the Board on April 6, 2016. He received a Bachelor of Engineering degree in Applied Chemistry, majoring in Electrochemical Production Technology, from Harbin Institute of Technology, China in July 1988. Mr. Ma is one of the founders of the Group. He joined the Group in August 2005 as the Chairman of the Board of Xinbang Industrial Co., Ltd. ("XPC"), a subsidiary of the Company. Mr. Ma is responsible for formulating and implementing the Group's overall strategic development, overseeing the execution of operational plans, and supervising the daily management of the Group's business. Mr. Ma has extensive experience in the manufacturing industry and is skilled in industrial management and operations of manufacturing enterprises.

Meng Jun

Executive Director

Mr. Meng Jun, born in 1966, is an Executive Director. He is primarily responsible for overseeing the Group's overall marketing operations and management. He was appointed as an Executive Director on April 6, 2016. He obtained a Bachelor of Engineering degree in Applied Chemistry from Harbin Institute of Technology in China in July 1988, majoring in Electrochemical Production Process. With a certificate issued by the Human Resources Department of Heilongjiang Province in September 1999, Mr. Meng obtained the qualification of Senior Engineer in Applied Chemical Industry. Mr. Meng possesses over 25 years of industry experience. Mr. Meng joined the Group in August 2004. From August 2004 to December 2009, Mr. Meng served as the General Manager of Tianjin Jinxin Precision Plastic Parts Co., Ltd. ("Tianjin Jinxin"), a subsidiary of the Company, responsible for overseeing its general operations and daily management. Since January 2010, Mr. Meng has served as the Marketing Director and has been responsible for overseeing the daily management of the Group's Marketing Department. Mr. Meng was appointed as a Director of XPC in October 2011.

Zhang Yumin

Executive Director

Mr. Zhang Yumian, born in 1966, is an executive director. He was appointed as an executive director on April 6, 2016, and joined the Group in April 2006. Mr. Zhang received a Bachelor of Engineering degree in Applied Chemistry, majoring in Electrochemical Production Technology, from Harbin Institute of Technology, China in July 1988. Since March 2023, Mr. Zhang has also been appointed as the Chief Executive Officer of the Group. Following the appointment, his main responsibilities are to supervise the business and management of the factories and departments under his charge.

Liu Jun

Executive Director

Mr. Liu Jun, born in 1976, is an executive director. He was appointed as an executive director on April 6, 2016. Mr. Liu joined Huizhou Haoyu Industrial Co., Ltd. (the predecessor of Huizhou Jianbang Electronics, one of our principal operating subsidiaries) in December 2002. Mr. Liu obtained a Bachelor of Science degree in Chemical Engineering from Hubei Three Gorges University, China in June 1998, and completed a one-year MBA program at the Higher Continuing Education College of Sun Yat-sen University, China in April 2007, and was awarded a graduation certificate. Since March 2023, Mr. Liu has also been appointed as the Group's Deputy Chief Executive Officer. Following the appointment, his main responsibilities are to supervise the business and management of the factories and departments under his charge.

He Xiaolu

Executive Director

Mr. He Xiaolu, born in 1975, is an executive director. He is primarily responsible for the Group's daily sales and marketing operations and management, in particular overseeing the business development and sales and marketing strategies of the Group's overseas subsidiaries. He was appointed as an executive director on April 6, 2016. Mr. He graduated from Fudan University, China, in July 1997 with a degree in History (Outbound Tourism). He graduated from the European University, Switzerland in June 2005 with a Master of Business Administration degree. Mr. He joined the Group in April 2006. In April 2006, Mr. He served as the Administration and Human Resources Manager, responsible for overseeing the administration and human resources management of XPC. From July 2007, in addition to serving as the Administration and Human Resources Manager, Mr. He also served as the Marketing Manager of XPC and was responsible for formulating and overseeing marketing strategies. From July 2008, Mr. He no longer held dual positions at XPC and focused on overseeing daily marketing management matters, in particular overseeing the business development and strategies of overseas subsidiaries. Mr. He was appointed as a director of XPC in October 2011 and as a director of Jianbang Europe in January 2008.

Jiang Wei

Executive Director

Mr. Jiang Wei, born in 1973, is an executive director. He is primarily responsible for overseeing the Group's operations and management. He was appointed as an executive director on April 6, 2016. Mr. Jiang obtained a diploma in administrative management from Shanghai Commercial Vocational and Technical College of China in July 2001. Mr. Jiang joined the Group in March 2004 as the general manager of Wuxi Jinxin Surface Treatment Co., Ltd. (“Wuxi Jinxin”), a subsidiary of the Company. At that time, he was responsible for managing and supervising the daily operations of Wuxi Jinxin, coordinating corporate resources to achieve business objectives, and maintaining key clients. In October 2011, Mr. Jiang was appointed as a director of XPC, responsible for overseeing the Group's operations and management. Mr. Jiang has over 10 years of management experience in the manufacturing industry.

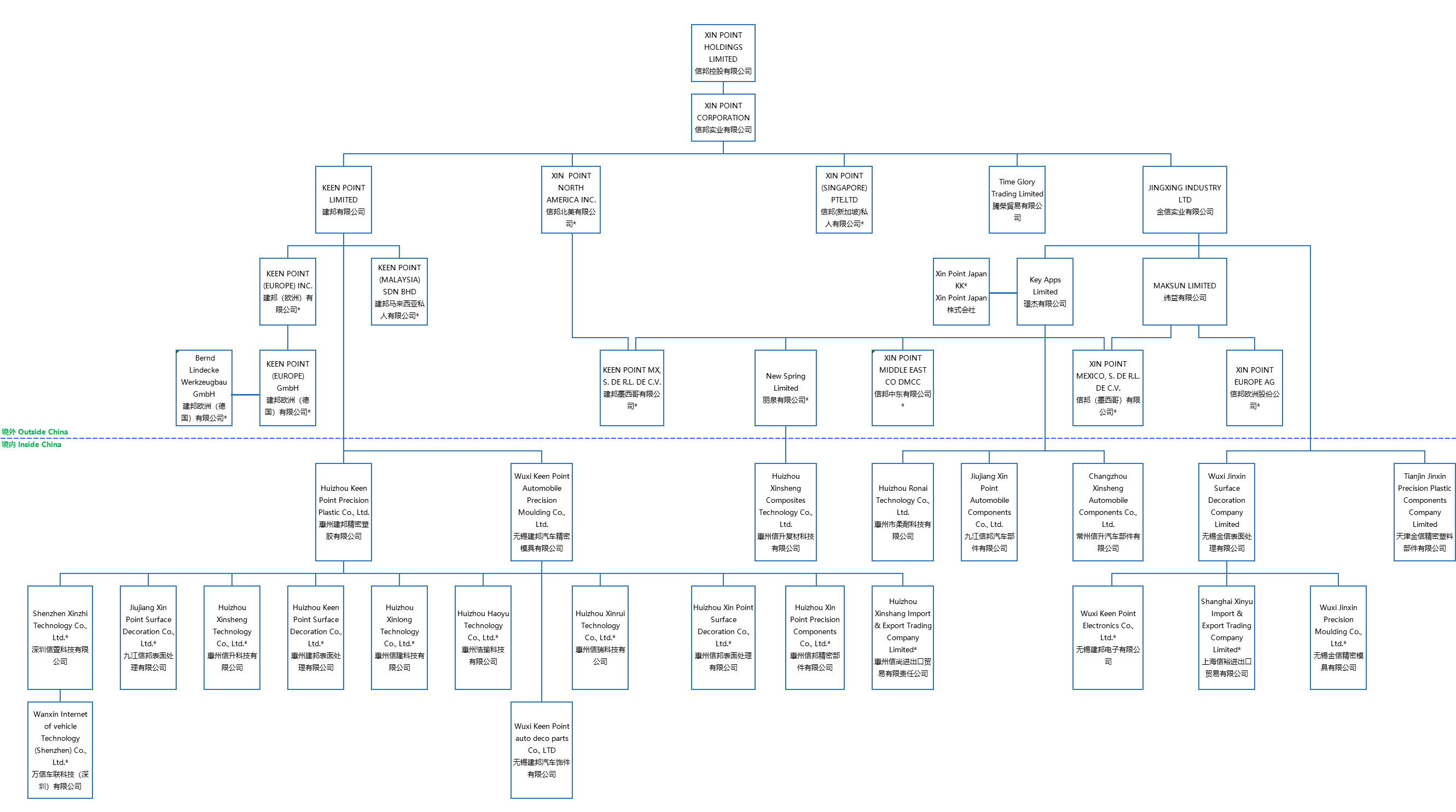

Organization